1) Motivation

In 1995 the Alfred P. Murrah Federal Building in Oklahoma City was target of a bomb blast attack, where 168 people died and hundreds were injured. Later investigations showed that 80 percent of fatal casualities were caused by glass splinters of the broken facade acting as missiles. As the number of blast attacks increased rapidly after the terror attacks on the World Trade Center in 2001, blast enhanced facades are more and more requested by clients.

2) Blast Load

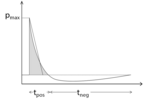

A bomb attack in front of buildings generates a blast wave, which hits the building after a split of second with a shock wave. The shock wave is characterized by a time-pressure-history starting with an instantaneous rise in peak reflected pressure decaying rapidly to zero, followed by a negative pressure phase with longer duration. However, it is common to simplify the time-pressure-history to an idealized triangular specific impulse load neglecting the negative phase.

3) Blast enhanced facade design

Main target in building and façade design is to protect people inside the building and to reduce damages in the facade and main structure to minimize the risk of building collapse. Focusing on the load path, the glazing has to be designed in a way, that it remains in the frame and defined hazard criteria (see next section) are fulfilled. The mullion/transoms and brackets can be designed in a way, that blast energy is dissipated. Mullion and transoms are able to dissipate energy by generating a plastic hinge, façade brackets can be designed as crash zone with dissipative materials.

4) Hazard criteria

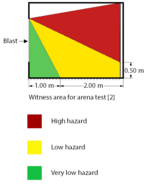

Before starting with technical evaluation of blast protection of buildings a hazard survey should be made by consulting engineers, in order to define blast load criteria, which is usually expressed as x kg TNT in y m standoff distance. In order to protect people inside the building a hazard rating of glazing or glazing system shall be made. There are different hazard levels depending on number, size, effects and location of fragments that lie at, or behind the glazing. ISO 16933 defines hazard rating criteria for arena tests of windows from A (no break) to F (high hazard).

5) Methods

Materials and structural components have different behavior with regard to strain rates. Most materials show for example higher strength under high strain rates compared to quasi static strength. There are different kinds of tests simulating the effects of pressure waves acting on structural elements.

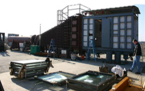

Arena tests are performed as bomb blast tests with defined TNT equivalent mass and a defined stand off distance to the target. This testing method is the most realistic, but also most extensive way of testing.

In shock tube tests a generated pressure wave is running through the tube hitting the test specimen at the end .

With high speed hydraulic machines the strain rate effect of materials and structural components can be analyzed. Here no pressure wave is generated, but the material and components are subjected to high strain

rates as they appear in real bomb blast events.

[1] Defense Visual Information Directorate, www.defenseimagery.mil

[2] ISO 16933:2007. Glass in building. Explosion-resistantsecurity glazing. Test and classification for arena air-blast loading

[3] Permasteelisa Group of Companies

[4] American Architectural Manufacturers Association

Current research projects

Abgeschlossene Forschungsprojekte